- JLM World Power

transformer kit, AC/DC (Ver. 2) 3 rail kit &

Power Station (Ver. 2) 5 rail kit & 24v Simple Zener Reg Power Supply kit

building info below

Kit Reviews here

- JLM

World Power kit is a fully fused & 120v/240VAC switchable 30VA PCB

power transformer to dual low voltage AC out.

- Kit can be ordered with 3

different transformers with either 2 x 9vac or 2 x 12vac or 2 x 15vac

outputs.

- This kit with either a AC/DC

or Powerstation kit will give you a full power supply solution that will

work anyway in the world.

- The

World Power PCB is 3.6" (91.5mm) wide x 2.5" (63.5mm) deep x 1.575" (40mm)

high with 30VA transformer fitted.

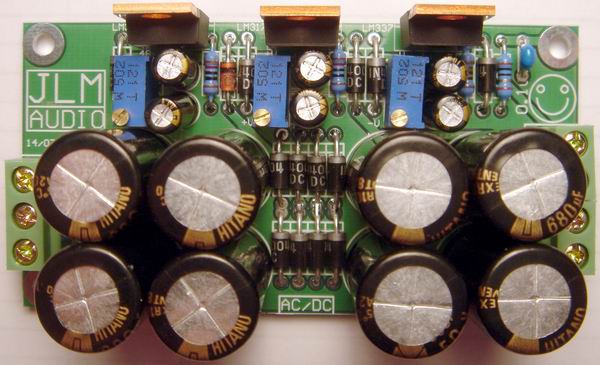

- JLM AC/DC

Ver. 2 kit is a Linear

based universal power supply with can generate 3 voltage rails from a single or

dual 24 to 30vac.

- It has one pump charge rail for 48vdc, 1 +/- Rails that can be

set from +/-2v to 37v by a 25turn trim pot.

- All regulators are on one edge for

easy heatsink or case mounting.

- Can supply 1amp per +/-V

rail and 300mA +48vdc. 1amp for +/'-V rails can be boosted to 1.5amp with 4

extra 1N4007 diodes.

-

The AC/DC Ver. 1 & 2 PCB is 3.3"wide (83mm) x

1.7"deep (43mm) x 1.1" (28mm) high from top of tallest cap to lowest solder

joint under the PCB.

-

- JLM Power Station

Ver. 2 kit is a Linear based universal power supply with can generate 5 voltage

rails from a single or dual 24 to 30vac. It has one pump charge rail for

48vdc, 2 +/- Rails that can be set from +/-2v to 37v by a 25turn trim pot.

- All regulators are on one edge for easy heatsink or case mounting.

- Can supply 1amp total shared

between both +/-V rail and 300mA +48vdc. 1amp total for +/-V rails can

be boosted to 2amp with 4 extra 1N4007 diodes.

-

The Power Station

Ver. 1 & 2 PCB is 4.06" wide

(103mm) x 1.7" deep (43mm) x 1.1" (28mm) high from top of tallest cap to lowest

solder joint under the PCB.

- JLM

Simple 24v zener kit is a very simple Linear based universal power supply with can generate

24v from a single 30v to 48vdc rail.

- It can do other output

voltages by changing to different voltage zeners or if running from a

regulated higher rail a resistor can be used in place of the zener.

- Using on of the 48v 380mA

SMPS prebuilt supplies and a simple zener kit is the easiest and cheapest

way to power 2 x 1073 , 1290, 1272 neve modules.

- Or 2 x V672 modules etc that

need 24v to run and 48v rail for phantom power. Because there is no power

transformer involved there is no hum problems due to coupling to the audio

transformers.

- Regulator

is on one edge for easy heatsink or case mounting.

- Can supply 1amp

-

The simple zener PCB is 1.2" wide

(103mm) x 1" deep (43mm) x 1.1" (28mm) high from top of tallest cap to lowest

solder joint under the PCB.

- ALL 120/240v mains wiring MUST

be done by a Qualified Technician.

- What Power Transformer

secondary volts do I need?

- The transformer secondary AC

volts needed depends on the +/- dc regulated voltage rails wanted. If you want

+/-34vdc regulated for 99v you will need 37v to 40v unregulated which would need

one or two 26vac to 28vac transformer secondary windings. This might sound like

a odd voltage value but in reality when you take the fully loaded voltage and

add the regulation percentage specified by the transformer manufacture to get

the no load voltage it all works out. So if the voltage output of a transformer

is stated as 25vac at full load by adding the 10 to 20% regulation amount you

will end up with 27.5vac to 30vac unloaded with is perfect. Also if you use one

25vac winding then the refresh rate to the large storage capacitors will be 50

or 60Hz depending on the country you are in. If you use two 25vac windings or a

50vac centre tapped winding the refresh rate will be 100Hz or 120Hz which will

almost half the amount of ripple on the large storage caps. Also the dual 25vac

has symmetrical ripple.

- Step by step build for

PowerStation Ver. 2 and AC/DC Ver. 2 kits

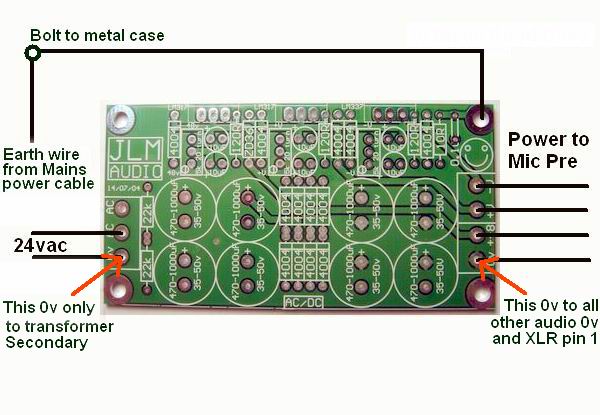

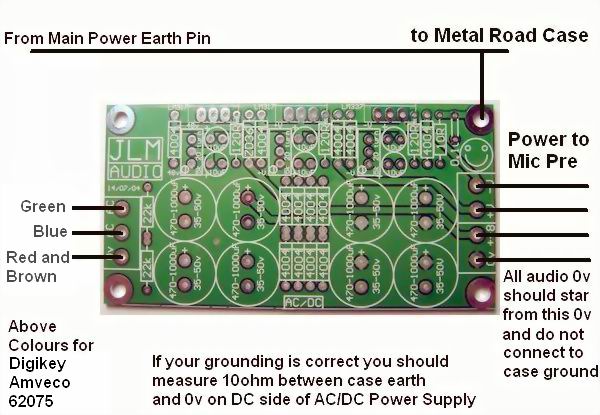

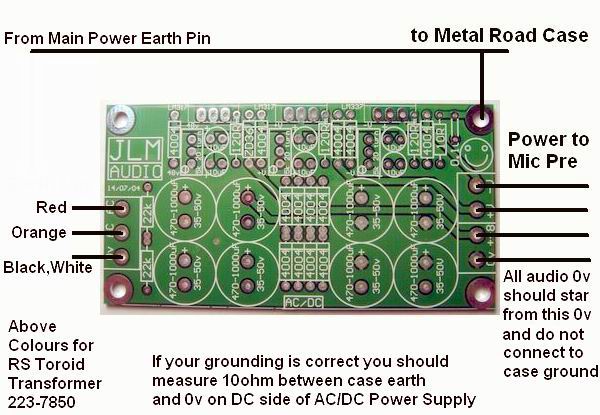

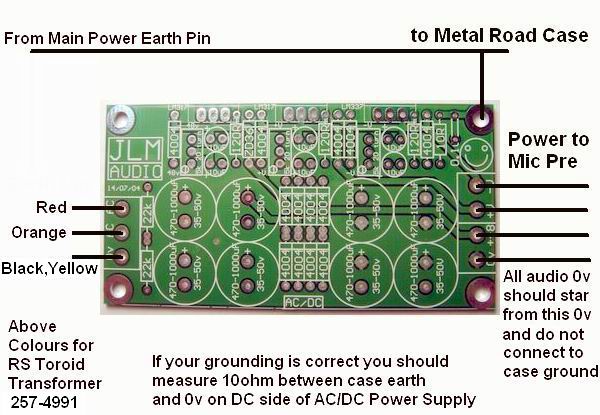

Below shows

correct Mains earthing and 0v connections which applies to AC/DC PCB and

PowerStation PCB

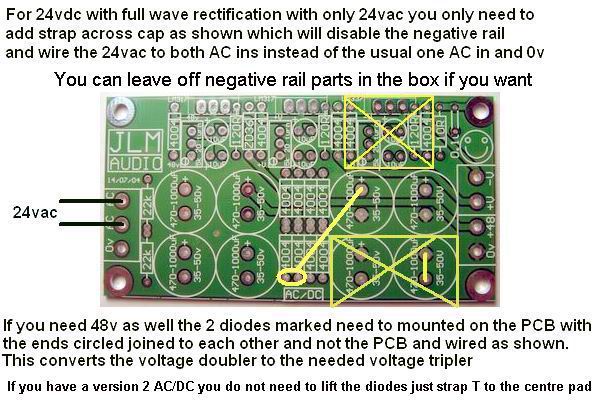

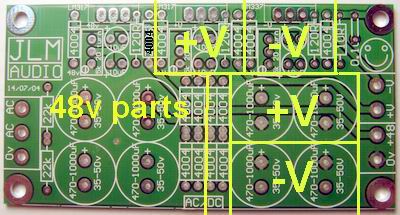

Below shows how to get +24vdc and +48vdc

from just a 24vac plug pack to run Neve or old Telefunken gear which requires no

negative rail. If using 2 x 22v to 2 x 25vac transformer no mod is needed and

negative parts can be left off.

Below shows shows colour code and

wiring for Digikey Amveco Toroid series of transformers.

Below shows shows colour code and

wiring for RS single mains voltage Toroid series of transformers.

Below shows shows colour code and wiring

for RS 120v/240v dual mains voltage Toroid series of transformers.

Old

Ver 1 AC/DC and Ver 1 PowerStation PCB's below are

Linear based universal power supplies with can generate 3 or 5 voltage rails from a

single or dual 24 to 30vac. It has one pump charge rail for 48vdc, 1 or 2 +/- Rails

that can be set from 5v to 34v by a resistor or 25turn trim pot. All regulators

are on one edge for easy heatsink or case mounting.

Old

JLML5RPSPCB below is a Linear based universal power supply with can generate 5

voltage rails from a single or dual 24 to 30vac. It has one pump charge rail for

48vdc, 2 +/- Rails that can be set from 5v to 34v by a resistor or 25turn trim

pot. All regulators are on one edge for easy heatsink or case mounting.

JLML5PSPCB is 4.3" (109mm) x

1.45" (37mm)

|

Capturing Audio without Injury

Capturing Audio without Injury Capturing Audio without Injury

Capturing Audio without Injury